Anticorrosive, anti-erosion and reconstructive protective coatings: what you need to know

- Cristian Polito

- Nov 20, 2023

- 2 min read

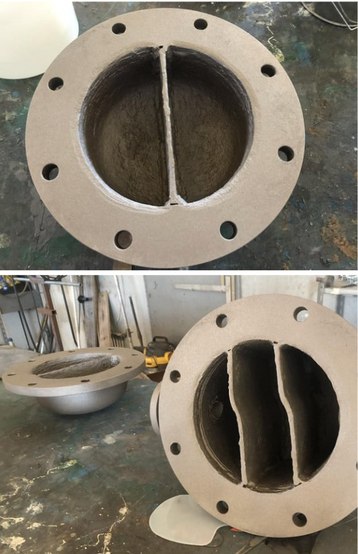

Our coatings impart high hydrodynamic properties to treated components, reducing fluid friction with surfaces and protecting the underlying metal from erosive and corrosive phenomena. The treatment is suitable for impellers, turbines, pump bodies, valves, filters, etc.

When it comes to preserving and prolonging the service life of equipment, structures and facilities exposed to corrosive and erosive agents, protective coatings play a crucial role. These coatings provide an effective barrier against the attack of aggressive substances, thus protecting against corrosion and wear caused by nature and the environment. In this article, we will explore the importance of corrosion and erosion protective coatings and their applications in various industries.

Corrosion and erosion: a common threat

Corrosion is a chemical reaction that occurs between metal and its environment, reducing the strength and durability of the material. In addition, erosion can occur due to friction and wear caused by solid particles such as sand, dust or highly corrosive liquids interacting with a surface. Both of these phenomena can cause significant damage to plant, structures and equipment, leading to costly downtime and repairs.

The solution: anti-corrosion and anti-erosion protective coatings

Protective coatings are formulated to provide an effective barrier between the metal substrate and the aggressive external environment. They offer protection against the corrosive action of acids, alkalis, moisture and other chemicals, thus preventing galvanic corrosion, crevice corrosion and other types of deterioration. At the same time, erosion-resistant coatings offer protection against wear caused by mechanical friction, improving the durability and efficiency of treated surfaces.

Applications and Industries

Corrosion and erosion protective coatings find application in a wide range of industrial sectors. The oil and gas industries, for example, benefit greatly from these coatings in offshore activities, where equipment such as drilling platforms are exposed to highly corrosive marine environmental conditions.

In the chemical industry, where aggressive chemicals are present in large quantities, protective coatings ensure the durability and integrity of equipment.

Furthermore, in the transport industry, both on land and at sea, protective coatings are essential to protect ship structures, bridges, storage tanks and transport facilities from damage caused by corrosion and erosion.

Conclusions

Protection against corrosion and erosion is a major challenge for modern industries. With anti-corrosion and anti-erosion protective coatings, it is possible to effectively counteract these phenomena and preserve the functionality, safety and durability of structures and equipment. Choosing the right type of coating for the context and using quality products is crucial to achieve the best results. Investing in corrosion and erosion protection is a safe investment in the future of industrial activities.

Comments